Abstract

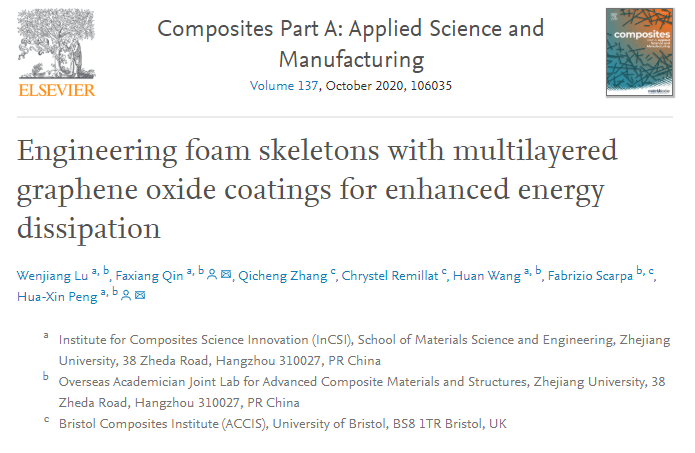

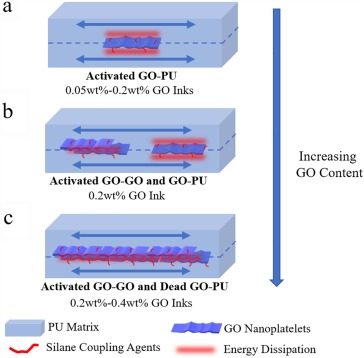

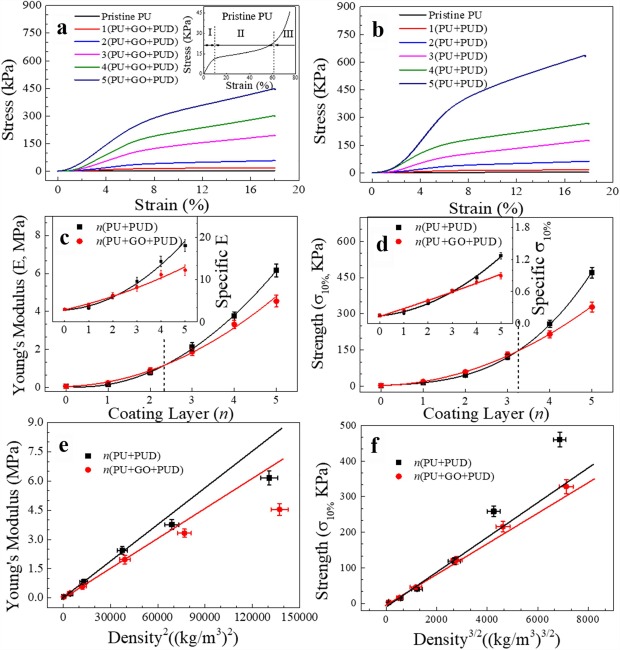

This work shows how to improve the energy dissipation of open-cell polyurethane (PU) foams by creating multilayered graphene oxide (GO) nano-architectures onto the struts via a modified dip-coating process. Pristine PU foams are alternately dip-coated with GO coatings and water-based polyurethane dispersions (PUD) for a given number of times. The GO coating morphologies are carefully adjusted and the inner energy dissipation mechanisms reach the optimized interfacial frictions of GO-PU and GO-GO. Along with the synergistic effect of the multiple interpenetrating structure of GO/PU coating phases, these engineered composite foams with extremely low GO content (~0.12 wt%) afford a significant increase of quasi-static energy dissipation (52%) and dynamic damping (76%) when compared with counterpart foams coated with the same number of pure PUD layers. The specific Young’s modulus and strength of the designed foams also show remarkable enhancements of 310% and 490% respectively compared with those of pristine PU foams.

Keywords

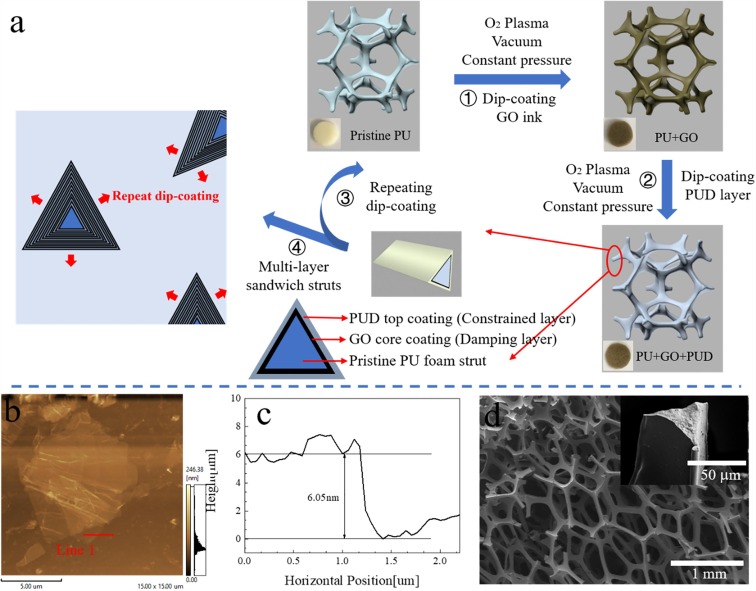

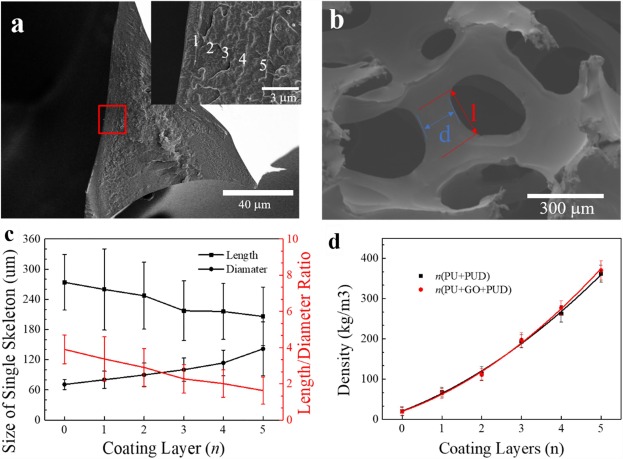

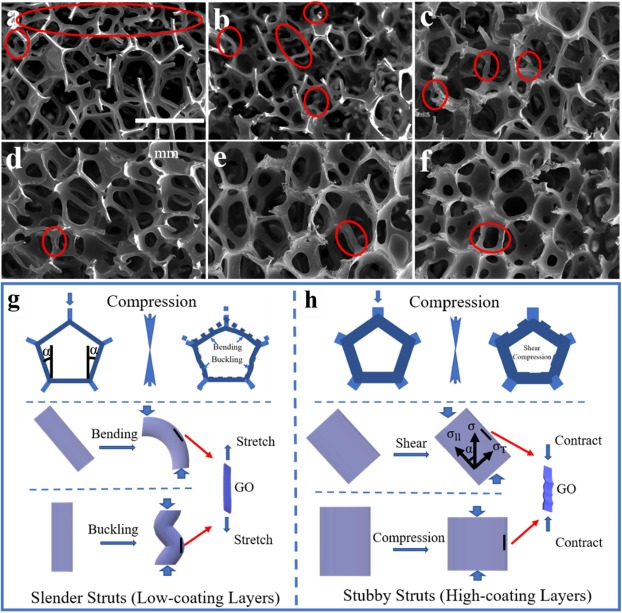

Fig. 2. SEM images of (a) PU foam struts coated with GO inks of different concentrations, (a1) pristine PU, (a2) 0.05 wt%, (a3) 0.1 wt%, (a4) 0.2 wt%, (a5) 0.3 wt% and (a6) 0.4 wt%, the rougher surfaces with the increasing concentrations of coating inks demonstrate more GO nanoplatelets attached on the surface. The surface morphologies of the struts coated with 0.2 wt%GO-ink under (b) low and (c) high magnifications, showing that the unfolded GO nanoplatelets are quasi-uniformly coated on the whole struts of the foams and form an entangled coating network with some sparsely uncovered PU areas.

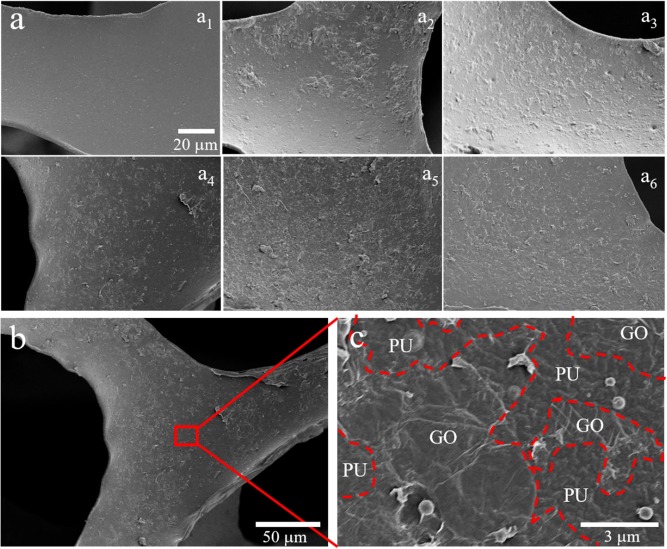

Fig. 3. SEM images of the sandwich structure of the foam struts. (a) The smooth surface of the PUD coating and (b) cross-section of PU + PUD samples brittlely fractured by an external force after liquid nitrogen treatment. Cross-sections of PU + 0.2 wt%GO + PUD samples (c, d) brittlely fractured after liquid nitrogen treatment and (e, f) gradually fractured at room temperature.

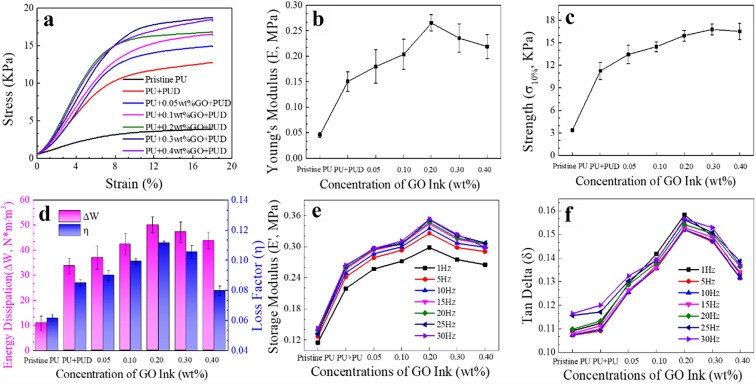

Fig. 4. The mechanical, quasi-static energy dissipation and dynamic damping properties of the sandwich structural foams coated with GO inks of various concentrations. (a) Stress–strain curves from compression tests and the derived (b) Young’s modulus (E) at 2%~3% strain and (c) strength (σ10) at 10% strain. (d) Energy dissipations (ΔW) and loss factors (η) obtained from quasi-static cyclic compression tests. (e) Storage modulus (E’) and (f) damping loss factor (tan δ) obtained by DMA under different frequencies.

Conclusions

In this work, PU foam skeletons with multi-layer sandwich GO coatings are successfully designed and fabricated by using a modified dip-coating method. The GO coatings work as the core layers of the sandwich architecture covering the whole surfaces of the foam skeleton and provide a satisfying energy dissipation mechanism of the GO-GO and GO-PU interfacial micro sliding under cyclic deformation. When compared with the counterpart foams without GO layers, the energy dissipations (loss factors) of composite foams with only ~ 0.12 wt% GO content increase by 52% and 76%, respectively, from quasi-static cyclic compression tests and DMA tests. These enhancements are atributed to the inner energy dissipation mechanisms performed by the optimized interfacial frictions of GO-PU and GO-GO and the synergistic effect of the multiple interpenetrating structure of GO/PU coating phases. Besides, the introduction of the PUD coating layers significantly enhances the Young’s modulus (310%) and strength (490%) of the foams compared with the pristine PU foams. This work provides an effective route to design and manufacture graphene nanocomposite foams for damping applications and affords insightful analyses for the structural mechanisms of this material under static and dynamic load.

Title:Engineering foam skeletons with multilayered graphene oxide coatings for enhanced energy dissipation

Website:https://www.sciencedirect.com/science/article/pii/S1359835X20302748#f0005

Work Group:https://person.zju.edu.cn/hxpengwork

Related Research Works:

Title:Large stiffness thermoformed open cell foams with auxeticity

Website:https://www.sciencedirect.com/science/article/pii/S2352940720302237?via%3Dihub

DOI:https://doi.org/10.1016/j.apmt.2020.100775

Title:Engineering Graphene Wrinkles for Large Enhancement of Interlaminar Friction Enabled Damping Capability

Website:https://pubs.acs.org/doi/10.1021/acsami.9b09393

DOI: 10.1021/acsami.9b09393